Sewage Treatment Plants

We Design, Fabricate, Supply, Erection and Commissioning Sewage Treatment Plants (STP) for treating sewage generated by Industry, large colonies, Hotels, Hospitals, IT Parks and commercial buildings.

As per new National pollution control norms, the Sewage Treatment Plant (STP) became statutory requirement of all the State Pollution Control Boards. Hotelier, Industrialist & Residential Complexes, Institutions are looking for economical, easy to install and operate compact type Sewage Treatment Plant as the land is extremely expensive.

We are one of the pioneers in this field offering the customised solutions as per the need of each segment.

The Principle

STP work on the principle of Aerobic Treatment with the help of aerobic bacteria, which is most conventional and proven method throughout the world known as anaerobic digestion.

Technologies Used

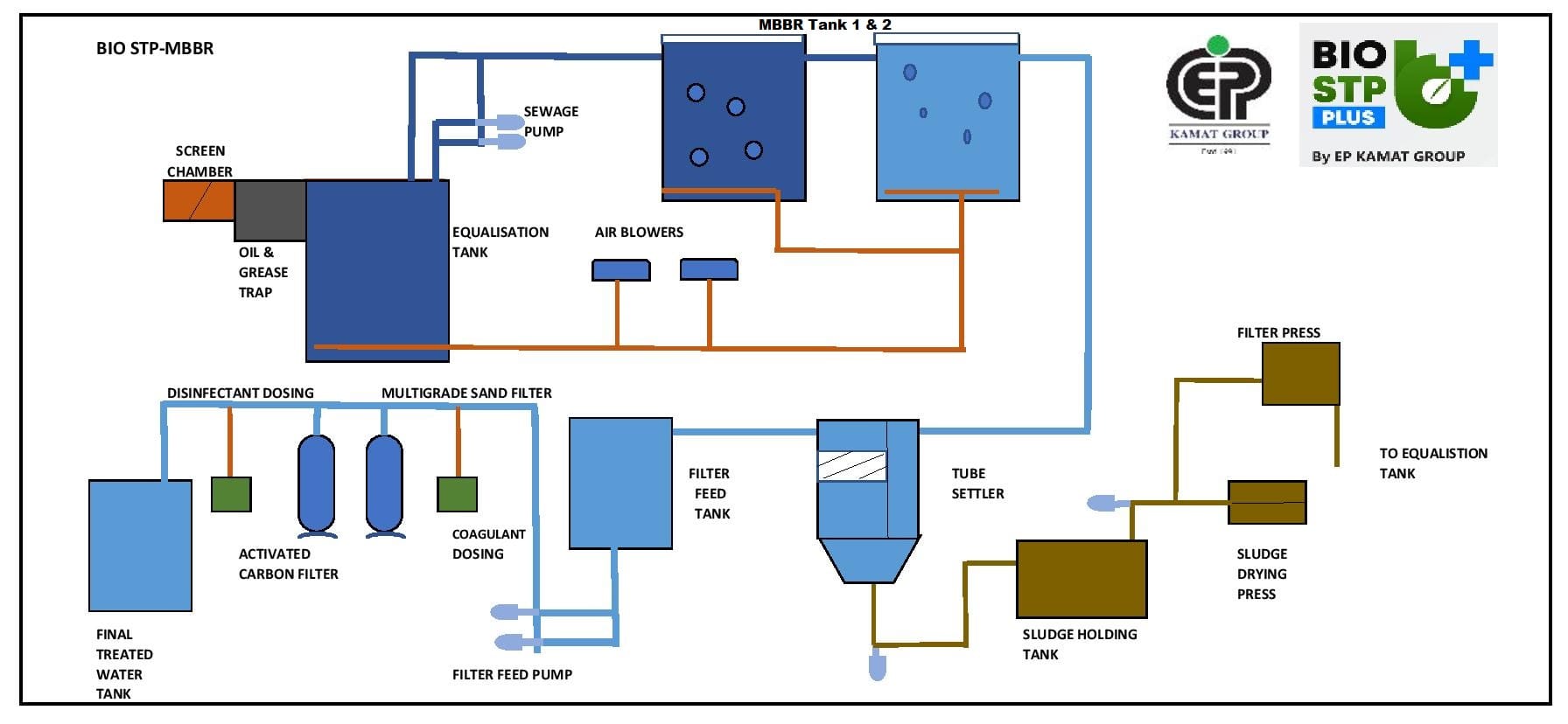

- MBBR: Moving Bed Bio reactor

- SBR: Sequential Bioreactor

- MBR: Membrane Bio Reactor

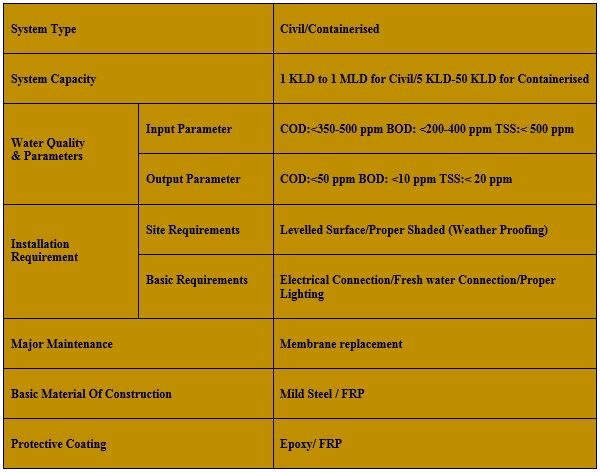

Flow Diagram

EP Biocomposites Ltd Offers following BIO STP

BIO STP Containerised Type

Capacity: 1– 50 KLD

Technology: MBBR / SBR / MBR

Features:

- Semi-automatic Operation.

- Required less space.

- Very Compact and aesthetic.

- Reduced Installation and commissioning time on site.

- Plug and play operation.

- Easy installation and transportation.

- Customised product.

- Civil Work – Collection Tank and Container Foundation.

Typical Industries: IT Complex, Hotels & Restaurants, Labour Camps, etc.

BIO STP- Civil Type

Capacity: 1 KLD TO 1 MLD

Technology: MBBR / SBR / MBR

Features:

- Semi-automatic Operation

- Minimum Maintenance Required

- Underground Civil Work (RCC) Construction

- Erection and commissioning by Trained and experienced EP Biocomposites Ltd Team

- Treated Water can use for Irrigation, Gardening, Flushing Purpose

Typical Industries: Large Societies, Hospitals, Hotels, Large Industries, Commercial Complex.

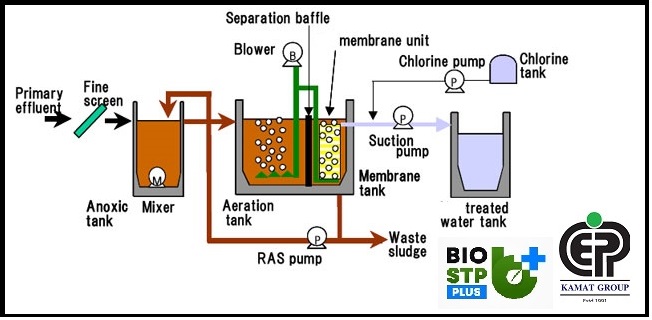

MBR: Membrane Bio Reactor

This technology is a combination of membrane process like microfiltration, nanofiltration, ultrafiltration with biological waste water treatment process. It is one of the most important innovation in waste water treatment as it overcome the drawbacks of the conventional ASP(ACTIVATED SLUDGE PROCESS), including large space requirement for secondary clarifiers, liquid–solid separation issues, production of excess sludge, and limitations with removal of recalcitrant. Its claimed ability to hold and sustain mixed liquor suspended solids (MLSS) of three to four times than what is possible in the conventional aeration tanks which in turn offers minimization of the footprint of the treatment plant. Diffused aeration is of course needed.

Flow Diagram