FRP Doors

FRP Stands for Fibre Reinforced Polymer. It refers to the way the door is made, with layers of GELCOAT, Resins & Glass mat laid down & chemically bonded together, to create a durable material which is of great use. FRP is extremely strong, highly resistant to chemicals and thermally neutral.

Why FRP

Wood has traditionally been the preferred material for building products, however it is a scarce resource and has led to serious environmental crises, including rapid depletion of forest cover. In the pursuit of finding suitable and superior substitutes, there has been extensive R&D for FRP (Fibre Reinforced Plastic) and GRP (Glass Reinforced Polymers).

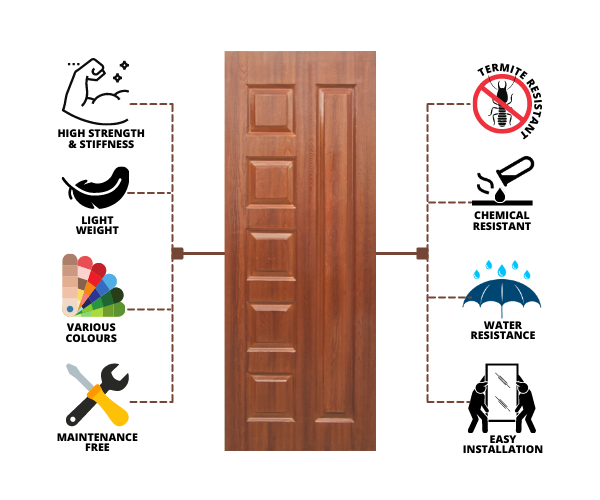

Advantages of FRP Doors

What makes us different

Shade Card

Gallery

Technical Specification Of Standard EPEE FRP Doors

| Thickness | 30/32/35 mm |

| Design | As per the designs available. We can produce a new design for project order of sufficient quantities and lead time |

| Width & Height | Standard |

| Width of Internal Stiles | 40 mm on all sides of seasoned Hardwood. Locks, Handles, fitting can be fixed |

| Skin | 1.5 mm thick Fibre Reinforced Polymer (FRP) |

| Core | EPS (Expanded Polystyrene) Block Board |

| Finish | Wood Grain Normal available colors Wood Finish |

Technical Specification Of Customizable EPEE FRP Doors

| Thickness | 30/32/35 mm |

| Design | As per the designs available. We can produce a new design for project order of sufficient quantities and lead time |

| Width & Height | Trimmable to 10 mm on all sides |

| Width of Internal Stiles | 40 mm WPC (wood Polymer Composites) frame on all sides. Locks, Handles, fitting can be fixed |

| Skin | 1.5 mm thick Fibre Reinforced Polymer (FRP) |

| Core | EPS (Expanded Polystyrene) Block Board |

| Finish | wood Grain Normal available colors Wood Finish |

Technology Partner & Certificates

Our Clients

Testimonials

“In the last 8 years our experience has indicated that the FRP doors supplied by EP Kamat Group are by far the best value for money.”

Shri Subhash D. Kurtarkar

Kurtarkar Real Estate

“We have been procuring FRP Shutters & Frames from EP Kamat Group since last 5 years and are extremely satisfied with the quality & timely delivery.

Eng. Guru Gani

Executive Engineer (Mormugao Port Trust, Goa)

“Delighted to visit EP Kamat Group and to see the scientific and systematic management and work force producing excellent and quality products. My best wishes for reaching greater heights.”